how to test hardness of materials|how to measure surface hardness : online sales Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as . Vídeo sobre Duas lésbica novas no escritório, mulher de negócio bonita que faz massagens a outra mulher e que flerta. Vídeo de receoso, laptop, aborrecimento - 119896999

{plog:ftitle_list}

3 dias atrás · NovelasFlix Assistir Novelas Online APK Download 2024. Bom, como o google nao gosta dele, por exibir novelas, voce pode tentar baixar no site oficial: Veja algumas coisas legais que ele tem: – .

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as .Hardness testing is an essential aid in the differentiation of materials, as well as for the analysis, development and improvement of materials and technologies within the framework of fundamental research (materials science, materials .

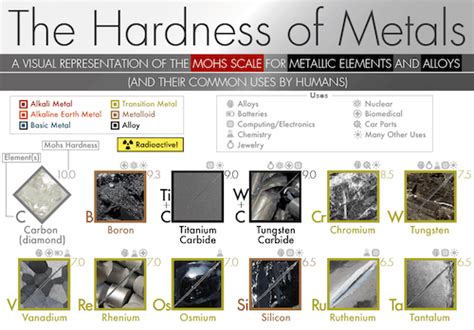

The hardness of the material is ranked on the scale between the material it just scratches and the material that it fails to scratch. Moh's Scale of hardness. Indentation testing. There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals .Vickers is a hardness test for all solid materials, including metallic materials. The Vickers Hardness (HV) is calculated by measuring the diagonal lengths of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically in order to determine the hardness .

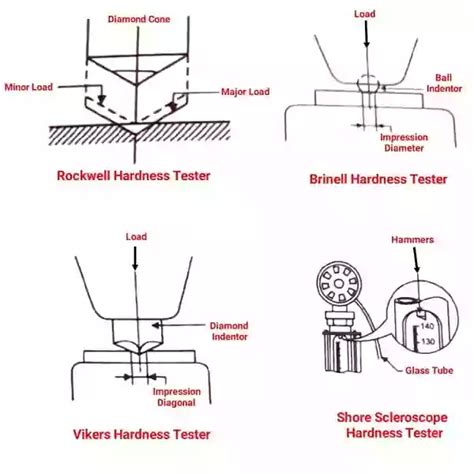

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to . The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5) Determining material hardness by measuring the diameter of the resulting indentations using a carbide ball or hardened steel is known as Brinell hardness test. For example, a ball approximately 10 mm in diameter is pressed into the surface of the material under an applied load commonly equal to 3,000 kgf for steels and 500 kgf for softer materials.

Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

The Vickerstest is a hardness test for all solid materials, including metallic ones. The Vickers Hardness (HV) is calculated by measuring the diagonal length of an indent in the sample material left by introducing a diamond pyramid indenter with a given load. The diagonals of the indent are measured optically to determine the hardness, using a .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material Characteristics • Test to check material • Test hardenability • Test to confirm process • Can be used to predict Tensile strength .Hardness testing assesses a material's ability to resist permanent deformation at its surface by applying pressure with a harder material. . ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials. ISO 6508: This standard is very similar to ASTM E18, as it deals with the Rockwell hardness tests, .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work.Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or .

Brinell Hardness Test: The Brinell hardness testing method is commonly used to test large or coarse-grained materials like nonferrous metals, castings, and forgings. This hardness testing involves applying a known load . Rockwell hardness test is a fast testing method found for production control, with direct reading, used primarily for metallic materials. Rockwell hardness (HR) is calculated by measuring the depth of the . Various hardness tests, from the Knoop hardness test to the Leeb hardness value, provide valuable insights into a material’s performance characteristics. Whether it’s the hardness measurement of a hollow vertical .

types of material hardness

The Vickers hardness test is similar to the Brinell test. However, it uses a four-sided inverted diamond pyramid with an apex angle of 136°. The Vickers hardness number (HV) is the ratio of the impressed load to the square indented area. The Vickers hardness test is of particular value for hard, thin materials where hardness at a spot is required. Understanding the idea of a material’s hardness and how to test it for hardness is a key part of the complicated field of material science. With a long past and a nature that is always changing, hardness testing has become an important way to judge the quality and suitability of materials in many industries.

Rubbing Color fastness Tester vendor

The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in. . For the lowest hardness test force, the 15 Kgf scales, a polished or lapped surface is recommended. Care should be taken when finishing any material prior to testing to avoid the .

Hardness testing methods vary based on the material and heat treatment chosen. It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common . How to Test Material Hardness? Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests: The Brinell Test: The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. . It involves scratching a material surface with reference materials of known hardness (e.g., minerals) and comparing the scratch patterns to determine the relative hardness of the material. While less precise than other hardness testing methods, the Mohs scale is useful for quickly assessing the hardness of minerals and geological specimens.

The hardness test is the key to check the mechanical strength of ceramic workpieces, which are easily affected by wear. For example, the hardness of bearing parts has a great impact on its performance - because the hardness of the bearing affects its wear resistance, and the wear caused by the poor wear resistance leads to the precision of . Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value. 10 minerals are ranked on the Mohs scale from low hardness to high hardness from 1 to 10 as shown in the below picture. Mohs hardness is not suitable for engineering fields as the hardness of .

types of hardness testing methods

types of hardness tester

WEB1 dia atrás · Se o telhado é de vidro, que seja de vidro temperado! Você merece o melhor, exija inox 444 e vidro temperado! O kit é composto de: 1 boiler fabricado em aço inox 444 de baixa pressão com capacidade de armazenamento de 600 litros e código mk 600 com (68 cm x 230 cm) + 6 coletor solar mc1300 tf10 - 69,8 kwh/mês coletor com vidro .

how to test hardness of materials|how to measure surface hardness